Our goal is to provide airport authorities and airfield lighting teams with the best equipment and tools that will considerably reduce and improve maintenance tasks.

Our solutions include mobile on-site or static airport workshop airfield lighting photometry and calibration, as well as airfield ground lighting maintenance and retroreflective markers for airports and heliports.

Visit our website for more information.

Airfield lighting

PAC² V5: photometric airfield calibration

Since October 2003, all airports have to submit compliance reports of their installations against the ICAO standards. In recent years, almost all civil aviation authorities have changed the rules of maintenance of airport lighting stressing the requirement of frequent photometric testing up to once a month for runway lighting.

With PAC² V5, you will be able to verify the compliance to ICAO, FAA and STAC standards for runways, taxiways and approach lights, including inset or elevated light.

The PAC² V5 can be installed on any vehicle and provide a real-time measurement report as the vehicle travels over the lights at a speed up to 60km/h. The bi-directional sensors strip of FB Technology system will reduce the measuring time by at least 50%.

In order to ensure the best alignment, the driver looks at a video monitor fed by a camera fitted on the PAC strip.

PAC² V5 is already used by many prestigious airports all over the world. Visit our website to know more and have an overview of our references.

PAC Lab II: workshop photometry controller

The PAC Lab II system improves the maintenance work, making it more efficient and accurate by providing the capability to control the light output of each fitting before installing them on site.

It enables to measure inset and elevated lights. Thanks to a specific cache to be installed on the sensors strip, runway or approach light fittings can be measured in a normally lit office room.

Beams of bi-directional fittings are measured automatically one after the other. This reliable, precise and quick system provides instant reports and need no adjustment prior measurements.

PACπ: PAPI calibration and measurement

The PACπ measures the PAPI lights and provides the measurement results according to the requirements of ICAO. Using a high-resolution camera, a spectro-photometer and lux sensors, the system provides all necessary information related to the aiming angles, the transition, the chromaticity and the isocandela diagram of the light beam.

PAXign

Airfield Signs need to comply with strict ICAO standards. Thanks to PAXign, save time with only ten seconds of measurement time, save resources with only one operator needed and get an instant report on a tablet.

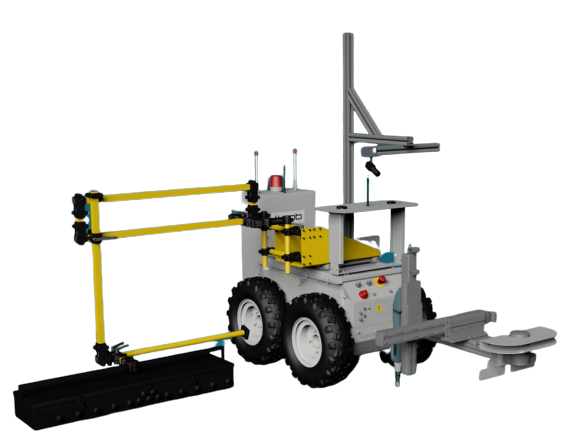

MARC One

MARC One is the latest innovation in airfield lighting testing. This revolutionary robotic platform performs multiple autonomous maintenance tasks. The robot runs through the runway autonomously and measures the AGL photometry quickly with its bi-directional sensors strip.

It also verifies automatically the torque value of the bolts and screws securing the inset light fixtures on their bases. MARC One performs the automatic cleaning of AGL lights, and measures and provides the iso-lux curves of airport aprons.

PAC Apron

The PAC Apron is designed to measure the lux values of the apron floodlighting and verify the iso-lux requirements as defined by ICAO, EASA and FAA. Installed on any vehicle, the immediate display of results and GPS co-ordinates of the measurement on-site are one of the many advantages of PAC Apron.

PAC MATRIX

PAC Matrix is a useful AGL photometric tester system that can be used on-site or in the airport workshop. It can control inset and elevated lights and is so easy to use that only one operator is needed. PAC Matrix is fast, precise, autonomous, hand portable and user-friendly.

AGL maintenance

SoDICE

SoDICE is the best airfield lighting cleaner today. Using pressurised soda bicarbonate or vegetal powder, storage is easy with no temperature or light constraints. SoDICE is also the faster equipment on the market as it only requires a few seconds per light to perfectly clean the prism with the highest efficiency.

This environment-friendly equipment is entirely dry. Therefore, it does not alter the prisms gaskets and no water can penetrate inside the fittings.

M-TAC

m-TAC is the latest innovation in airfield torque for the maintenance of airfield ground lighting. The integrated GPS will indicate the position of the operator within 1m. This torque wrench is highly reliable and productive, provides an immediate report, is very user-friendly and ensures traceability.

DICE

DICE is an airfield ground lighting cleaning equipment using cryogeny. The system can be installed in a vehicle or on a trailer for quick intervention. DICE is working whatever the climatic conditions.

Retroreflective markers for airport and heliport

Dedicated to delimitate taxiways or runway edges and the traffic and / or apron edges, the retroreflective markers complement the lighting of turn-pad areas.

Installation is easy and done by our highly experimented staff. Visible at 360° by day and night, this equipment is frangible on impact and has excellent resistance to jet blasts. It is maintenance-free and electrical-free.